Featuring full hydraulic operation, it includes a back pressure valve, high-pressure hydraulic filter, two-way balance valves, and special hydraulic lines for plateau conditions.

This wrecker has the functions of lifting, pulling, lifting, etc. It is convenient, quick, good-looking, safe and reliable. This truck wrecker is widely used in highways, public security traffic police, airports, terminals, auto repair industry and highway companies, etc.

Wrecker truck equipped with lifting winch device and wheel bracket which can lift, towing, back load and transport.Widely used in road, police traffic, airports, docks, auto repair company, industry and highway departments, timely, fast clean-up accident, failure, illegal and other vehicles.

Road wrecker is used for safety salvage of vehicles subject to city road, suburb way, highway, airport and bridge road. It is suitable for medium and small-sized cargos, cars and other special vehicles, which are allowed within the technical parameters of this kind

The tow wrecker is called the road wrecker, also known as road rescue vehicle. It has many functions such as lifting, pulling and lifting traction.

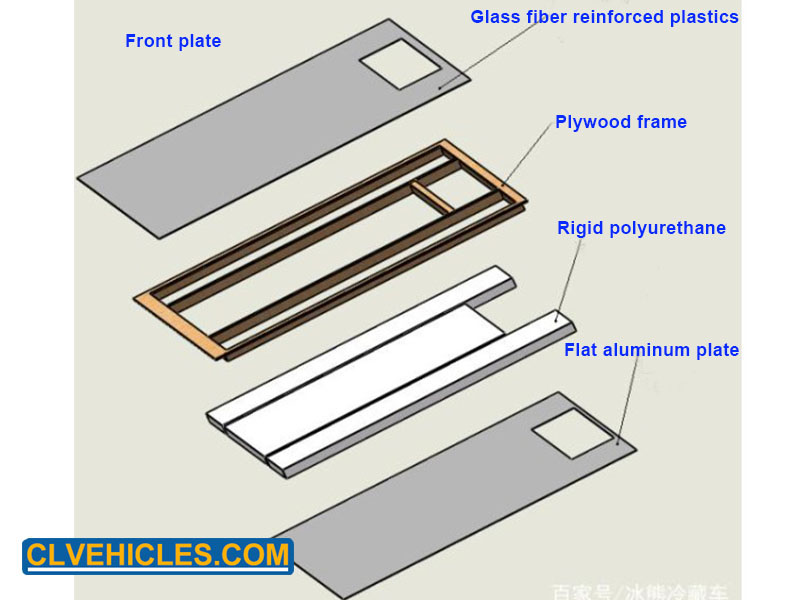

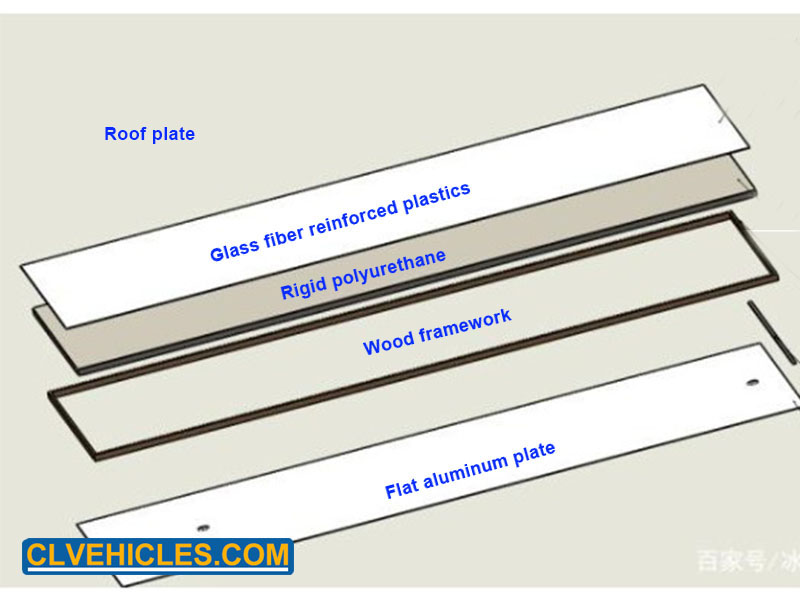

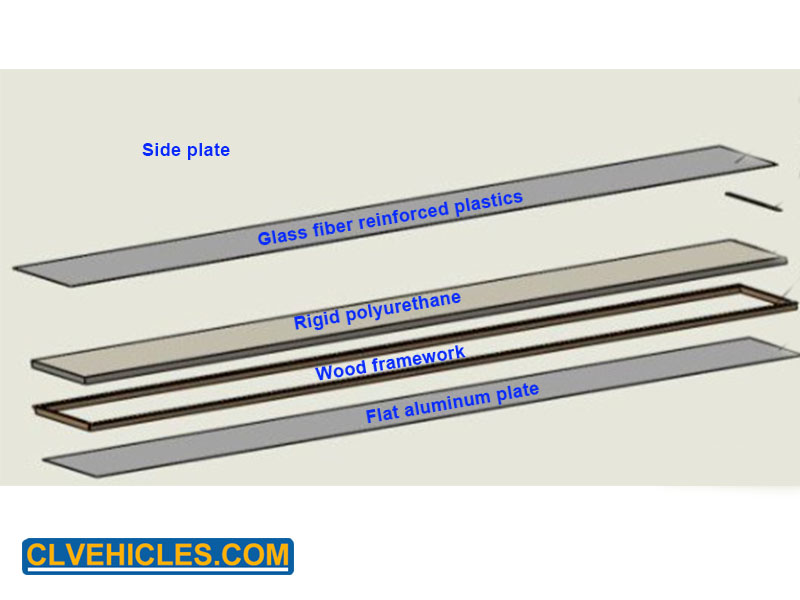

The refrigerated box adopts the general large-board assembly structure of the typical refrigerated box truck, which is composed of 6 large panels, including the front panel, the rear door panel, the top panel, the bottom panel, and the left and right side panels. The connection is bonded with two-component structural glue, and the exterior is riveted with aluminum alloy profiles. A 2.5mm thick SUS304 stainless steel rear door frame is set at the rear of the box board.

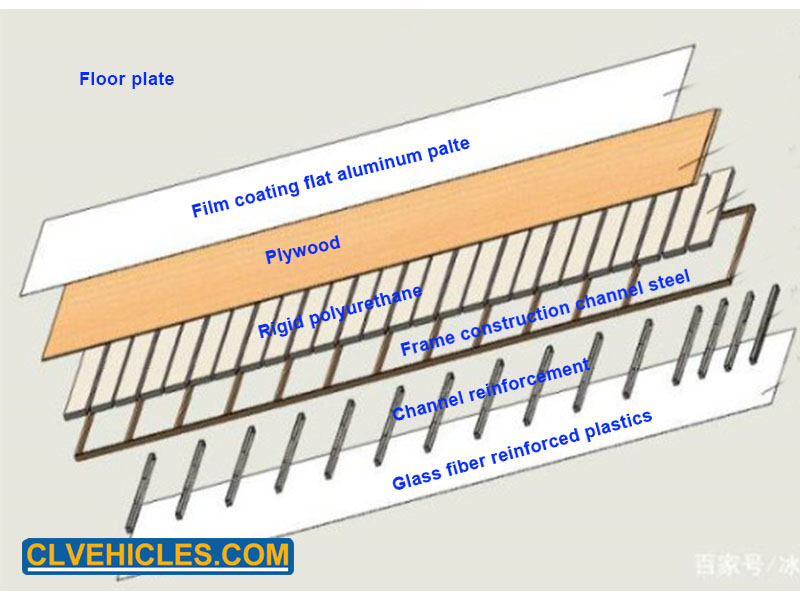

Each board of the refrigerated box is a composite board structure, and the inner and outer cover boards and the core material are pressed into a sandwich composite board by the adhesive. The outer skin of the refrigerated box is made of glass steel plate, thickness=2.6mm; the inner skin material: coated anticorrosive flat aluminum plate, thickness=1.2mm.

Insulation material: rigid polyurethane foam board (density 45~48kg/m3, thermal conductivity: 0.018~0.023W/㎡·K, compressive strength: ≥0.2Mpa, adaptable temperature: -50℃~+70℃); adhesive: Two-component structural adhesive.

Bottom: The outer skin is glass steel plate, and the inner skin is anticorrosive flat aluminum plate; the upper surface of the bottom plate is covered with a layer of 18mm thick waterproof plywood. The channel steel profile and wood plywood frame are set under the plywood, which can not only block the cold bridge inside and outside the compartment, but also It can strengthen the overall structural strength of the bottom plate and increase the carrying capacity of the refrigerated box. The total thickness of the bottom plate is 90mm. The bottom plate is equipped with a rectangular aluminum alloy profile and a duckbill-type drainage device.

Front plate: The front plate is embedded with the embedded parts of the independent refrigeration unit and has an opening; the total thickness is 80mm. Install accessories such as ventilation slots on the front panel.

Top plate: There is pre-embedded iron inside the top plate, with a total thickness of 90mm; accessories such as ceiling lights, evaporators, and unit protection nets are installed.

Left and right side panels: the total thickness is 80mm, and corresponding embedded parts are embedded according to the structural requirements, and accessories such as ventilation slots and pipe cargo slots are installed.

Rear door panel: the total thickness is 80mm, the rear door panel is an openable plate, and hardware accessories such as hinges and door locks are installed. Corresponding embedded parts are embedded according to the structural requirements.

The design of the back door frame structure: The design of the back door frame ensures that the back door can be opened at 270 degrees. The material of the rear door frame is t=2.5mm SUS304 stainless steel plate, which is connected with the refrigerated box by round head screws on the outside, and double-reinforced by countersunk screws and rivets on the inside. The rear door frame and each plate are separated by ABS plastic material to prevent production cold bridge.

Refrigerated box seal design: Reliable sealing is an important condition to ensure that the compartment air leakage and heat leakage rate are at a high level. At the same time, reliable sealing can prevent the heat leakage rate of the compartment from increasing during use.

a) Structural seal

The assembling parts of the compartment panels are all designed with steps to increase the sealing length of the assembling section and improve the structural strength of the assembling parts. The joint surfaces of the compartment panels (including the rear door frame and the compartment panels) are coated with refrigerated box assembly glue to achieve reliability seal.

b) Sealing of inner floor

The joints between the periphery of the bottom plate, the side plates and the front plate are bonded and sealed with polyurethane structural glue.

c) Sealing of door and door frame

The back door and the door frame adopt the universal labyrinth rubber strip and the effective control of the door gap to achieve reliable sealing.

d) Install sealant on the openings and switches of the lamps in the compartment.

e) Installation and sealing of refrigeration unit

The refrigeration unit is equipped with a sealing ring and sealant at the interface with the compartment body according to the product requirements. The pipes and lines of the refrigeration unit passing through the compartment plate must be sealed with sealant at each passage, and the fixing screws of the unit pass through the compartment plate. The place should also be sealed with sealant.

Refrigerated box assembly process

The assembled refrigerated box should meet the following requirements:

1) The diagonal error of the refrigerated box should comply with JS-024-2004 "Quality Inspection Requirements for Main Parts".

2) The refrigerated box assembly structural glue coated on the joint surface of each car board is uniform, full of gaps, and tightly sealed.

3) The screw connection is firm and reliable, and the outer screw holes of the compartment plate are coated with the compartment body assembly structure glue.

4) The door frame and the refrigerated box are connected firmly and reliably, and the connecting screws are arranged neatly.

The assembly process of the compartment panel: bottom panel installation→front panel installation→right side panel installation→left side panel installation→rear door frame installation→top panel installation→rear door panel installation.

related products: light duty refrigerated truck, heavy duty cooling van

online service

online service 0086-2787058417

0086-2787058417 0086-7223801382

0086-7223801382 info@chengli-trucks.com

info@chengli-trucks.com truck0809

truck0809 8615072324118

8615072324118