Featuring full hydraulic operation, it includes a back pressure valve, high-pressure hydraulic filter, two-way balance valves, and special hydraulic lines for plateau conditions.

This wrecker has the functions of lifting, pulling, lifting, etc. It is convenient, quick, good-looking, safe and reliable. This truck wrecker is widely used in highways, public security traffic police, airports, terminals, auto repair industry and highway companies, etc.

Wrecker truck equipped with lifting winch device and wheel bracket which can lift, towing, back load and transport.Widely used in road, police traffic, airports, docks, auto repair company, industry and highway departments, timely, fast clean-up accident, failure, illegal and other vehicles.

Road wrecker is used for safety salvage of vehicles subject to city road, suburb way, highway, airport and bridge road. It is suitable for medium and small-sized cargos, cars and other special vehicles, which are allowed within the technical parameters of this kind

The tow wrecker is called the road wrecker, also known as road rescue vehicle. It has many functions such as lifting, pulling and lifting traction.

A、Overview

The new series of low-pressure vehicle fire pumps have the characteristics of excellent performance, high efficiency, compact structure, beautiful appearance, simple operation and convenient maintenance. At the same time, the pump casing adopts a guide vane type, and the impeller adopts a balance ring and balance hole structure, which greatly reduces The axial force and radial force increase the life span. All performance indicators meet the GB6245-2006 standard, and have passed the type test of the National Fire Equipment Quality Supervision and Inspection Center.

The company's low-pressure series of vehicle fire pumps are currently upgraded products of domestic fire pumps, and are comparable to similar foreign products. It is an ideal replacement product for fire fighting truck refitting plants. It is suitable for refitting light, medium and heavy water tankers, foam fire vehicles, High injection vehicles, etc., can also be used to fix pump sets.

B、Main performance parameters

|

Item Model |

Inlet(mm) |

Outlet (mm) |

Max. vacuum degree(KPa) |

Vacuum reduce in 1min(MPa) |

7m suction depth time(s) |

|

|

|

CB10/20 |

φ100 |

φ65 |

≥8 |

<1.5 |

25 |

|

CB10/30 |

φ100 |

φ80 |

≥85 |

<1.5 |

25 |

|

|

CB10/40 |

φ125 |

φ80 |

≥85 |

<1.5 |

25 |

|

|

CB10/60 |

φ150 |

φ100 |

≥85 |

<1.5 |

43.6 |

|

|

CB10/70 |

φ150 |

φ100 |

≥85 |

<1.5 |

44 |

|

|

CB10/80 |

φ150 |

φ100 |

≥85 |

<1.5 |

44 |

|

C、Main structure and function

1. Main structure

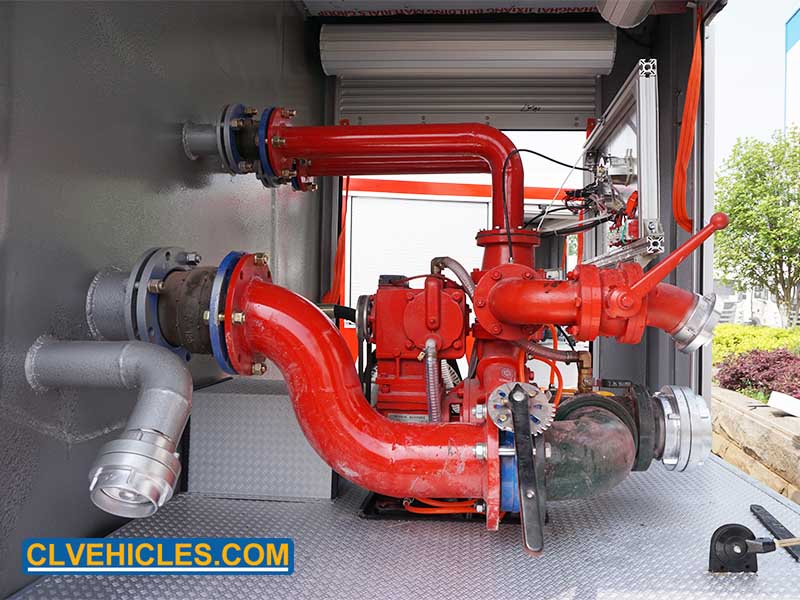

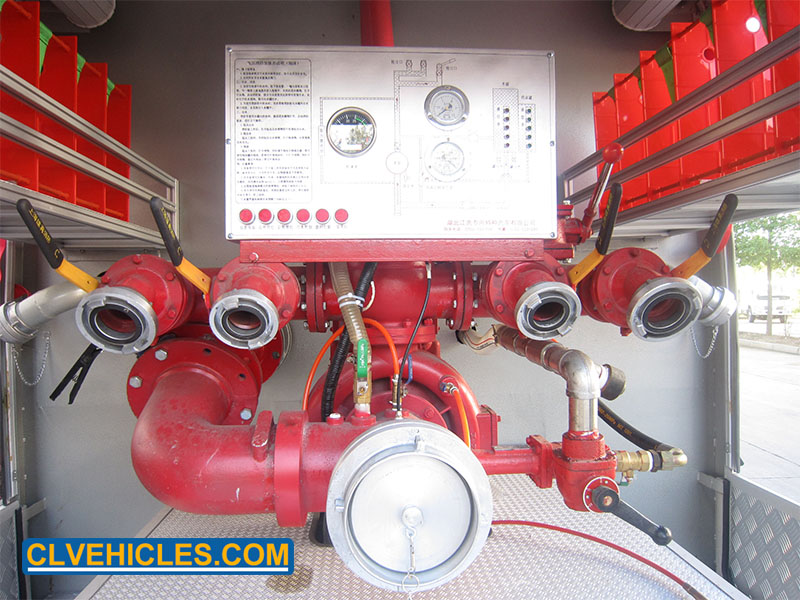

The low-pressure series of vehicle fire pumps are composed of a water pump part, a bearing box and a gearbox in two specifications, a water outlet pipe and a water inlet pipe, and a new piston water guide.

2.Function

(1) The water pump part is composed of a pump casing, a pump cover, a pump shaft, an impeller, a mechanical seal, etc. which are integrated with a guide vane chamber and a pressure water chamber.

The new series of low-pressure vehicle fire pumps use space guide vanes for diversion, so that the radial force on the pump shaft can be balanced; the back of the impeller adopts a balance ring and has a balance hole, thereby balancing the axial force on the pump shaft and improving The efficiency and service life of the pump. The pressure end of the pump shaft adopts a mechanical seal, which greatly improves the sealing performance.

(2) Priming part: 20, 30, 40, 60, 70, 80 pumps adopt a new type of double-piston water initiation without refueling, consisting of piston pump body, eccentric mechanism, piston, intake and exhaust valve plate, automatic disconnection device and electromagnetic clutch, etc. Composition, installed on the gearbox. The piston pump has a pulley on the pump shaft and a belt drives the pulley on the piston pump. When the water diversion device is started, the piston makes the piston reciprocate under the action of the eccentric mechanism to start water diversion. When the pressure reaches 0.2Mpa, the pressure controller automatically cuts off the power supply and automatically stops working.

(3) The gearbox is a first-stage helical gear transmission. The box is filled with lubricating oil and is equipped with a radiator. The pump introduces pressure water to cool the oil temperature in the box, thereby improving the transmission efficiency of the gearbox and improving the gears and bearings. Transmission conditions. The gearbox gear ratio is determined by the engine speed and the power take-off speed ratio. In order to facilitate the user to choose when refitting, the gearbox has different speed ratios.

Z1: Z2 (active: driven): 29: 32, 30: 31, 31: 30, 32: 29, 33: 28, 34: 27 (30, 40 series pumps are preferred), 35: 26, 36: 25 (60, 70, 80 pumps are preferred), 37:24, 38:23, 39:22, 40:21, etc.

(4) There is a water diversion valve installed in the water inlet pipe, which must be opened when diverting water, otherwise the air in the pump and water inlet pipe cannot be discharged, resulting in failure to divert water. After the pump is used, the remaining water is drained and the water diversion switch is closed.

D、Operation

1. Preparation before operation

⑴ All the residual water switches on the pump must be closed;

⑵ The foam fire truck must close the foam pipeline ball valve and the foam proportional mixer;

⑶ Open the water diversion valve on the water pump inlet pipe;

⑷ Close the water injection ball valve and the rear water inlet valve of the water tank;

Warning: The gearbox oil level must be checked before pump operation, and oil must be added when insufficient. Otherwise at your own risk!

2. Priming

When pumping water, there are three different operation methods depending on the water source

⑴Use water in water tank;

Start the fire pump, open the butterfly valve from the tank to the water pump inlet pipe, and open the water outlet ball valve. At this time, adjust the hand throttle to adjust the speed of the water pump to the required flow and pressure.

⑵Use water from fire hydrant;

① Take out the suction pipe (or hose, water collector) and fire hydrant wrench.

② Connect the water inlet of the fire pump to the fire hydrant with a suction pipe (or hose or water collector).

③ Use a fire hydrant wrench to open the fire hydrant valve to make the water flow from the fire hydrant into the pump, start the fire pump, open the water ball valve, adjust the hand throttle, and adjust the speed of the water pump to the required flow and pressure.

Note: When using the fire hydrant to supply water, the vacuum meter switch must be turned off, otherwise the vacuum meter will be damaged.

⑶Use water from rivers, ponds, and wells;

① Take out the suction pipe, water filter, and suction pipe wrench.

② Connect the suction pipe to a suitable length, install the water filter at the end of the suction pipe, and connect the other end of the suction pipe

Install on the water inlet of the fire pump, and sink one end of the installed water filter into the water source.

Note: There should be no air leakage at each connection of the suction pipe; the water filter sinks into the water source, and the distance to the water source is about 0.5 meters from the upper end of the water filter to the water surface. If it is too shallow, it will produce vortex when pumping water and affect the flow rate. But at the same time, it is not allowed to touch the sludge at the bottom of the river to prevent the suction of sludge and debris, which will block the suction pipe and damage the fire pump. The butterfly valve after the water inlet must be closed during the water diversion operation.

③ Start the fire pump, turn on the power switch of the water pilot, and the electromagnetic clutch is engaged. Start the piston pump

Adjust the hand throttle to the rated input speed. The piston pump quickly creates a vacuum in the suction pipe and the water pump cavity, and introduces water into the low-pressure impeller. The water pressure leads to the pressure switch on the water outlet. When the water outlet pressure reaches 0.2 After Mpa, the electromagnetic clutch is automatically disengaged, the piston pump stops working, and the fire pump starts to discharge water. At this time, turn off the power switch of the water diversion device.

④ Adjust the hand throttle to adjust the speed of the water pump to the required flow and pressure.

online service

online service 0086-2787058417

0086-2787058417 0086-7223801382

0086-7223801382 info@chengli-trucks.com

info@chengli-trucks.com truck0809

truck0809 8615072324118

8615072324118