Featuring full hydraulic operation, it includes a back pressure valve, high-pressure hydraulic filter, two-way balance valves, and special hydraulic lines for plateau conditions.

This wrecker has the functions of lifting, pulling, lifting, etc. It is convenient, quick, good-looking, safe and reliable. This truck wrecker is widely used in highways, public security traffic police, airports, terminals, auto repair industry and highway companies, etc.

Wrecker truck equipped with lifting winch device and wheel bracket which can lift, towing, back load and transport.Widely used in road, police traffic, airports, docks, auto repair company, industry and highway departments, timely, fast clean-up accident, failure, illegal and other vehicles.

Road wrecker is used for safety salvage of vehicles subject to city road, suburb way, highway, airport and bridge road. It is suitable for medium and small-sized cargos, cars and other special vehicles, which are allowed within the technical parameters of this kind

The tow wrecker is called the road wrecker, also known as road rescue vehicle. It has many functions such as lifting, pulling and lifting traction.

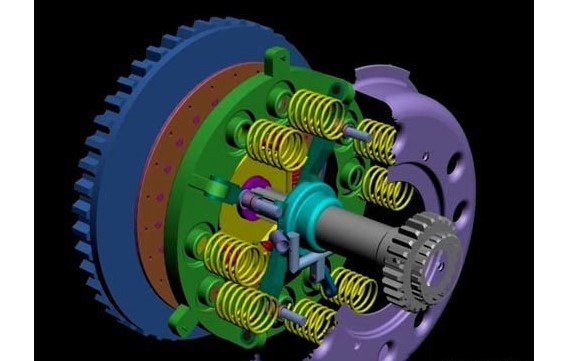

The development clutches

The first generation of the clutch is a flat belt (personally inferred to be the centrifugal clutch on the scooter). However, the transmission efficiency of the belt is too low and the wear is very serious, especially in the rainy days, the power transmission is more prone to problems. As the gearbox position increased and the clutch continued to withstand greater torque, a variety of clutches were invented, including the pioneer of modern clutches, the clutch based on the friction principle.

Since the clutch needs to be switched between separation and coupling, the spring is definitely an essential component. The older drivers know that the previous truck clutches used coil springs, some in the middle and some in the outer ring. Instead of these springs inside the clutch, they are replaced by a set of plates with claws. In fact, these claws are also a kind of spring, which is called "diaphragm spring".

Diaphragm springs - more comfortable and more reliable

Everyone knows that the tighter the coil spring is pressed, the more elastic it is – that is, the deeper the clutch pedal is, the harder it is. However, the diaphragm spring is different. It is the most elastic when it is deformed to a certain extent. If it continues to deform, the elasticity will become smaller. That is to say, the deeper the clutch pedal is, the more it does not necessarily sink.

For overloaded vehicles, it is clear that the coil springs provide more spring force to hold the clutch plates and ensure power output. However, for the standard vehicle, no excessive elastic force is required. If the loading point of the diaphragm spring is selected, the clutch pedal can be made lighter and more labor-saving while reducing the fatigue of the driver while ensuring the pressing force.

At the same time, for the coil spring clutch, as the wear of the friction plate becomes thinner, the spring-shaped variable is surely smaller, so the pressing force is surely gradually reduced, but the diaphragm spring will first become larger and then smaller.

Today's heavy-duty truck clutches - single-push diaphragm spring clutch

In order to transmit more torque in the early years, the heavy-duty clutch used two friction plates, namely a two-plate clutch. However, the two friction plates are prone to cause incomplete separation, so in recent years, with the improvement of material technology, the heavy truck has gradually changed into a single-piece clutch.

In addition, the possibility of disassembling the clutch has been seen. Some clutches are separated by the "paws" in the middle of the clutch, and the clutches are separated, while others require the bearings to be pulled out to pull the "paws". This is actually the two structures of the clutch: the pull clutch and the push clutch. The pull-on clutch pawl has a top inward and push-out outward.

Due to the structural problems, the pull-type clutch can use a larger diameter diaphragm spring to provide greater compression force and transmit more torque when the pressure plate is the same size, or to transmit the same torque. Use a smaller size. Therefore, the pull-type diaphragm spring structure is more compact and the advantages are more obvious.

online service

online service 0086-2787058417

0086-2787058417 0086-7223801382

0086-7223801382 info@chengli-trucks.com

info@chengli-trucks.com truck0809

truck0809 8615072324118

8615072324118