Featuring full hydraulic operation, it includes a back pressure valve, high-pressure hydraulic filter, two-way balance valves, and special hydraulic lines for plateau conditions.

This wrecker has the functions of lifting, pulling, lifting, etc. It is convenient, quick, good-looking, safe and reliable. This truck wrecker is widely used in highways, public security traffic police, airports, terminals, auto repair industry and highway companies, etc.

Wrecker truck equipped with lifting winch device and wheel bracket which can lift, towing, back load and transport.Widely used in road, police traffic, airports, docks, auto repair company, industry and highway departments, timely, fast clean-up accident, failure, illegal and other vehicles.

Road wrecker is used for safety salvage of vehicles subject to city road, suburb way, highway, airport and bridge road. It is suitable for medium and small-sized cargos, cars and other special vehicles, which are allowed within the technical parameters of this kind

The tow wrecker is called the road wrecker, also known as road rescue vehicle. It has many functions such as lifting, pulling and lifting traction.

Engine braking, also known as engine retarder, is a relatively low-cost auxiliary brake that is now standard on many heavy duty trucks .

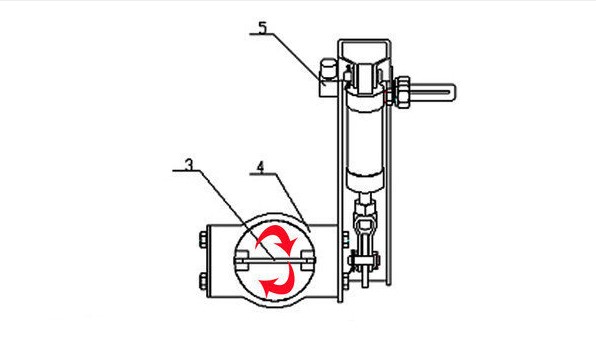

1. Exhaust brake

Exhaust brake is one of the most familiar forms. It is also very simple. It is installed by adding a butterfly valve to the exhaust pipe, and increasing the pressure of the exhaust stroke by closing the valve, and using the generated negative pressure to obtain the system. power. The cost is relatively low and the structure is simple.

This device is almost standard in domestic trucks, including light trucks. However, the exhaust brake is easily affected by factors such as damage to the exhaust manifold gasket, air leakage from the butterfly valve, unstable operation, and low braking power, which cannot meet the demand of heavy-duty trucks.

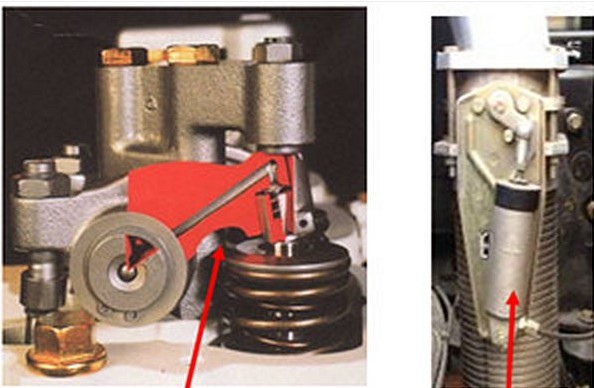

2. Deflated engine brake

Deflated engine braking, also known as exhaust valve braking, is divided into passive and active.

Passive requires an exhaust brake butterfly valve to match. When the engine brake switch is actuated, the exhaust brake butterfly valve is first closed, so that a high back pressure is formed in the exhaust pipe of the vehicle, so that the exhaust valve opens at a small angle, and then an exhaust mechanism is caused by a set of actuators. This valve opening is maintained during each stroke, and the compressed air leaks out from the exhaust valve during the entire compression stroke, reducing the energy returned to the piston to achieve the effect of braking deceleration, but the passive butterfly valve is affected by the working state. Large, especially when the engine speed is relatively low, the effect is relatively poor.

Passive requires an exhaust brake butterfly valve to match. When the engine brake switch is actuated, the exhaust brake butterfly valve is first closed, so that a high back pressure is formed in the exhaust pipe of the vehicle, so that the exhaust valve opens at a small angle, and then an exhaust mechanism is caused by a set of actuators. This valve opening is maintained during each stroke, and the compressed air leaks out from the exhaust valve during the entire compression stroke, reducing the energy returned to the piston to achieve the effect of braking deceleration, but the passive butterfly valve is affected by the working state. Large, especially when the engine speed is relatively low, the effect is relatively poor.

3. Compression release

Compressed release engine braking is the current mainstream engine braking technology, and it is also the one with the highest braking power and efficiency. When the control switch is turned on, the engine exhaust valve is opened near the top dead center of the compression stroke, and the high pressure gas formed during the compression stroke is discharged out of the engine cylinder. In this way, most of the energy absorbed by the compressed gas is emitted, and only a small portion of the residual energy pushes the engine piston back. As the engine repeats, the inertia of the vehicle as it descends will be dissipated by the engine's compression-release action, eventually decelerating the vehicle.

Simply put, compression-release engine braking is to turn the engine into an air compressor. In this way, the braking power is large. In order to improve the adaptability, it is divided into two gears. In the first gear, only four cylinders produce braking effect, and the second gear and six cylinders all participate in the work to achieve different adaptation. The purpose of weight and slope.

CLVEHICLES.COM has gained more than 15 years mature experience in special truck industry.

HOT products: ISUZU Auxiliary Engine,JMC Auxiliary Engine.

online service

online service 0086-2787058417

0086-2787058417 0086-7223801382

0086-7223801382 info@chengli-trucks.com

info@chengli-trucks.com truck0809

truck0809 8615072324118

8615072324118