DONGFENG 4x2 Light-Duty 18m Concrete Pump Truck

The boom can be rapidly and accurately repositioned by coordinating the movement the first and second sections. Strong power system reduced the rate of occurring faults.

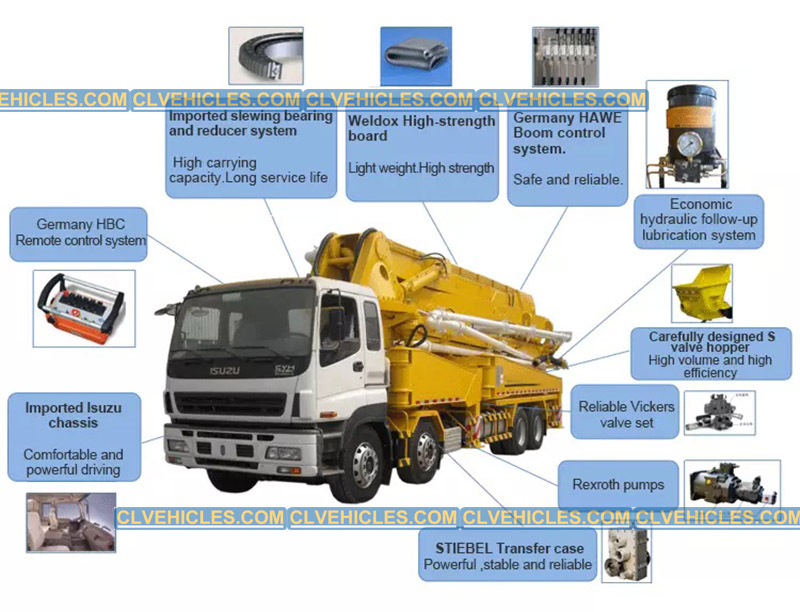

Featuring full hydraulic operation, it includes a back pressure valve, high-pressure hydraulic filter, two-way balance valves, and special hydraulic lines for plateau conditions.

This wrecker has the functions of lifting, pulling, lifting, etc. It is convenient, quick, good-looking, safe and reliable. This truck wrecker is widely used in highways, public security traffic police, airports, terminals, auto repair industry and highway companies, etc.

Wrecker truck equipped with lifting winch device and wheel bracket which can lift, towing, back load and transport.Widely used in road, police traffic, airports, docks, auto repair company, industry and highway departments, timely, fast clean-up accident, failure, illegal and other vehicles.

Road wrecker is used for safety salvage of vehicles subject to city road, suburb way, highway, airport and bridge road. It is suitable for medium and small-sized cargos, cars and other special vehicles, which are allowed within the technical parameters of this kind

The tow wrecker is called the road wrecker, also known as road rescue vehicle. It has many functions such as lifting, pulling and lifting traction.

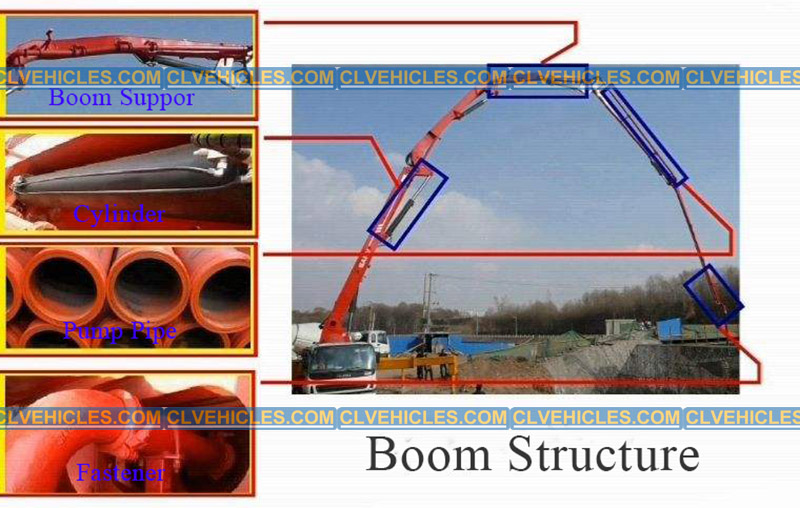

The boom system is designed by Multi physics analysis and testing. The steel is made by imported HSLA (High strength low alloy steel). All the welding are 100% inspected to ensure the structure rational and high reliability.

Brand:

CLVEHICLES.COMModel No.:

CLW5350THB50X-5RZMinimum Order Quantity:

1 UnitPrice:

USD 121,900 FOB ShanghaiPayment Terms:

T/T, L/C, Western UnionDelivery Time:

25~35 days after we get the depositShipping:

Ro-Ro/Bulk cargo/Container shipment / SKD / CKD / etc

SHACMAN RHD 6x4 Heavy-duty 38m Concrete Pump Truck

Adopt "R" type folding boom sections easy for special project. And the boom speed is adjusted

Sleeplessly, with compensated pressure, proportion system of sensitive to loading, as assure the flexible working of the boom. Maximum shock-absorbing controlled by multiple valve controller.

Pumping System: Tungsten steel glass plate and cutting ring guarantee the long using life. Automatic retraction of the concrete piston provides a more convenient and easier maintenance for the pumping system.

Automatic accelerator tracking system adjust the accelerator according to the actual pumping condition to save more diesel oil.

Hydraulic & Electrical System: Adopt double pumps with double circuits system and world famous hydraulic components. Variable displacement axial piston pump make the swing cylinder more stable and powerful. Operated by manual/panel/radio remote controller(NBB)

Quick Details

12/7Mpa

Chassis brand

SHACMAN

Dimension of vehicle

12230x2550x4000mm

Gross weight of vehicle

35000kg

Placeing boom at Max. height

38

Ratating angle of each arm

90°/180°/235°/180/180°

Max. Theoretical

throughput (high/low pressure)

50/80Mpa

Max. Concrete outlet pressure

Conveying cylinder inner diameter/stroke

Φ230x1650mm

Feeding height

1450mm

Concrete distribution valve form

S tube

Applications

The concrete pump truck is a modern construction machinery that integrates the transportation of finished concrete and the pouring process, to continuously, uniformly and promptly convey the premixed concrete to the form-work.

The application of pump trucks and the superiority of the pumping process make the pump trucks widely used in the construction of large concrete structures such as:

1) high-rise and super-high-rise buildings;

2) underground and tunnel projects;

3) port docks and dam projects;

4) roads and bridges and culvert projects.

Competitive Advantage

A. The continuous working pumping system blocks the segregation of concrete, hence the slump of the concrete will not be amplified, which visibly guarantees the quality of the construction operation.

B. The concrete pump truck concurrently solves the horizontal and vertical transportation also, pouring problems of concrete with high mechanization required few labor. The construction organization is simple yet suitable for structural materials thanks to high compressive strength it occupies.

C. The concrete pump truck casting operation requires continuous operation, with high construction efficiency and fast operation progress. Additionally, the similarity of expansion coefficient of concrete and steel bar resulted in intensive bonding strength contributing to reinforced concrete with a wider application range.

D. The concrete pump truck posses strong adaptability to the construction work surface with wide range of operations, the pipeline can be laid to places that are difficult to reach by other equipment. The concrete pump truck can fill and cast the concrete in place under a certain pressure, and also can be used in series to increase the output distance required during construction.

Product Details

Customer Services

Pre sale service

--- Technical communication with engineer

--- Factory and workshop visit

--- Making design drawings

After Sale Service

--- Overseas installation & commissioning

--- Overseas and spare parts support

--- Technical and spare parts support

Truck

According to your request, choose good chassis and refit it to truck.

Upper Body

design function parts.

Customization

Spare Parts

on trucks as tank and box.

Supply only upper body without chassis. According to your chassis drawing,

Communicate with engineer,making design drawings and produce customized products.

Supply all kinds of spare parts on chassis and upper body,replace main parts

Product Parameters

|

Truck Specification |

|

||

|

Truck model |

CLW |

||

|

Cab |

Shacman F3000 cab with A/C |

||

|

Driving Type |

6*4 Right hand drive |

||

|

Max Speed (km/h) |

90 |

||

|

Overall dimension(mm) |

10910×2510×3750 (for ref) |

||

|

Wheelbase(mm) |

4375+1400 |

||

|

Tire |

12.00R20 |

||

|

Clutch |

Single-plate dry diaphragm spring clutch |

||

|

Steering |

Hydraulic steering with power assistance |

||

|

Gear box |

12speed |

||

|

Bridge |

Front axle |

7.5T |

|

|

Rear axle |

13T |

||

|

Engine |

Model |

WP10.340E22 / EURO II |

|

|

Fuel Type |

Diesel fuel |

||

|

Type |

Water-cooled .four-stroke, direct injection, turbocharged |

||

|

Max output power/rotate speed (hp /rpm ) |

340hp |

||

|

Braking system |

Service Brake |

Compressed air brake |

|

|

Park Brake |

Spring energy |

||

|

Auxiliary brake |

engine exhaust brake |

||

|

Eletric system |

24v |

||

125

|

Upper part specification |

||

|

Boom system |

Maximum vertical height (m) |

38 |

|

Boom horizontal radius (m) |

33.5 |

|

|

Depth(m) |

22 |

|

|

Rotating angle of each section(°) |

90/180/180/229/212 |

|

|

Boom control mode |

Load-sensitive proportional control |

|

|

Boom Sections |

5 |

|

|

Boom fold type |

RZ |

|

|

Turret rotation angle |

360° |

|

|

Span of front outriggers (m) |

6800 |

|

|

Span of rear outriggers (m) |

8350 |

|

|

Longitudinal distance between the front and rear legs |

6800 |

|

|

Outriggers open type |

X-R |

|

|

Diameter of concrete conveyor pipe(mm) |

125 |

|

|

Electronic control system |

Control power |

24V |

|

Control module |

Schneider |

|

| Working voltage |

24V |

|

|

Remote control |

HBC |

|

|

Hydraulic transmission system |

Hydraulic system type |

Open type |

|

Transfer box brand |

Germany Stiebel |

|

|

Main oil pump brand |

Germany Rexroth |

|

|

Pump balancing valve brand |

Germany Rexroth |

|

|

Pump multi- valve brand |

Germany HAWA |

|

|

Valve group |

American Eaton |

|

|

Hydraulic oil tank volume (L) |

500 |

|

|

Pump system |

Rated pump qty (M3/h) |

83~140 |

|

Pressure (MPa) (high pressure/ low pressure) |

12/8 |

|

|

Type of reversals of the distribution valve |

S |

|

|

Diameter of the cylinder (mm) |

230 *1550 |

|

|

Maximum loading height (mm) |

1450 |

|

|

Volume of hopper (L) |

500 |

|

|

Concrete slump |

160-220 |

|

|

Max material allowed (mm) |

40 |

|

online service

online service 0086-2787058417

0086-2787058417 0086-7223801382

0086-7223801382 info@chengli-trucks.com

info@chengli-trucks.com truck0809

truck0809 8615072324118

8615072324118